Following on from Hotel Designs’ Spotlight On’ feature of Technology last month, editor Hamish Kilburn sat down with the marketing manager of Hamilton Litestat to explore lighting trends, clever ways to illuminate the guestroom and how products are changing…

Last month, Hotel Designs lit up the conversation around in-hotel technology and where trends are heading in the near future of hotel design. One conversation that came up time and time again was the idea of designers using lighting in more savvy ways to create a certain ambiance. With this in mind, I decided to ask the experts at Hamilton Litestat who are ahead of the curve and in-the-know when it comes to the future of lighting technology in the guestroom and beyond.

Hamish Kilburn: How has lighting recently become more of a focus in guestroom design?

Gavin Williams: Lighting has always played a significant role in the guest experience of a hotel. First impressions count and from the moment a guest sees the hotel building and walks into reception, lighting is being used to create a statement about the hotel.

Lighting control certainly doesn’t need to be complicated

Within a hotel’s guestrooms, lighting control provides important functionality. In the week, many guests are business people who need to use their rooms as a place of work during the day. Then, in the evenings – as well as weekend guests – they want to use the space to relax. Lighting control transforms these spaces between the different functional requirements, easing from bright work-appropriate lighting into softer mood lighting at the touch of a button or swipe of a finger.

This also applies to the function rooms, restaurants and bars within a hotel. The atmosphere – and therefore the lighting requirements – for breakfast is very different to an evening meal setting, so lighting control can support this space transformation too.

We take the brief and turn it into the desired solution with no headaches

HK: I think a lot of designers shudder at the thought of lighting control in the guestroom. Can you put their minds at ease by telling us what makes Hamilton’s products user friendly?

GW: Lighting control certainly doesn’t need to be complicated. From a designer’s perspective, all they need to do is tell Hamilton what effects they want to achieve, and our team will deliver a pre-programmed system to suit. Designers don’t need to know the ins and outs of how the system works, that’s Hamilton’s job! We take the brief and turn it into the desired solution with no headaches.

Our solutions offer a range of effects, so designers should consider the result they’re after and whether they’d like dimming control, the ability to mix light and colour with DMX options, or the ability to set scenes. If they’re unsure, they can visit Hamilton’s showrooms in Bristol or at the Mere facilities to talk through the options and see demonstrations so they have the confidence that the system will deliver their lighting ideas.

And, even more importantly, our smart lighting control solutions make things simple for guests too. They can be controlled by simple yet elegant button switches that are available in a range of designs, easy-to-use glass control panels or via an accessible app on a smart device.

We’ve found exhibitions such as Decorex, The Independent Hotel Show and the recently rebranded SLEEP+EAT particularly helpful for keeping abreast of the latest trends

HK: Do you keep track of trends, and what lighting products are most popular for hotels?

GW: Yes, we make sure we take notice of the lighting trends within the hotel sector, and the general design trends. Both are very important to our business. Our smart lighting control solutions can help achieve these looks, but as we also design and manufacture decorative wiring accessories, we offer switched plates and sockets with the latest on-trend finishes.

We’ve found exhibitions such as Decorex, The Independent Hotel Show and the recently rebranded SLEEP+EAT particularly helpful for keeping abreast of the latest trends. We exhibit at these shows and have both hoteliers and designers visit our stand, so we often find ourselves discussing current trends and themes that require lighting control. We also participate in the Hotel Designs networking events, which we find very useful. Hamilton’s solution is very flexible and can be programmed to deliver more complex solutions as and when new trends and requirements come in, but we’re also always happy to build a bespoke system to meet a specific design brief.

HK: Can you explain the creative elements with regards to what goes into designing a new product?

HK: Can you explain the creative elements with regards to what goes into designing a new product?

GW: Products are bought, not sold, so new product development must be driven by talking to customers and uncovering what is missing from the current market offering, or what is not working with existing products on the shelves. In terms of the crucial elements when designing a new product, function and form has always been important to Hamilton and balancing these two elements is something we pride ourselves on. We ensure our products deliver smooth, seamless and effective functionality in a product that’s attractive and well-designed.

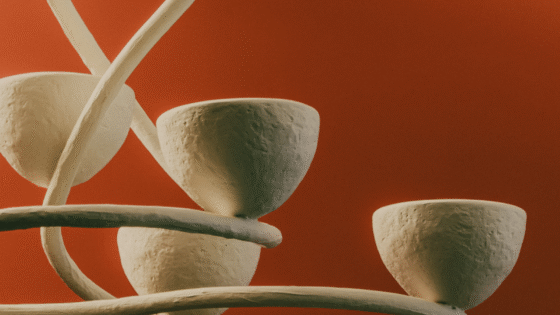

In a hotel, the bulk of any lighting control system will be installed out of view in the hotel’s hub room. It’s only the control plates that are visible in guestrooms so, typically, a designer wants to create a special control plate, one that has a unique shape or finish to coordinate with other wiring accessories in the design scheme.

The majority of Hamilton’s products are manufactured in our factory in Bristol

As pioneers in the manufacture of decorative plates for switches, sockets and lighting controls, Hamilton has accrued 50 years’ experience in meeting the specifications of designers and hoteliers. We simply need some guidance on the function, style and finish that’s being sought, and we will interpret these wishes to provide a suitable solution. The Hamilton design team can offer 3D CAD drawings so that customers can view product designs from different angles and perspectives to ensure it meets the most exacting requirements. This also shortens the lead time from design to product sampling. We’re also happy to create highly finished sample prototypes for a designer to present to their client to help them buy into their design ideas.

HK: How are Hamilton Litestat products made?

Image caption: Gavin Williams

GW: The majority of Hamilton’s products are manufactured in our factory in Bristol: we’re a family-run business producing British-quality solutions. Our production facility includes complete CNC, Laser and Water Jet Cutting capability. In addition to our standard selection of finishes, we can provide bespoke premium finishes, including PVD, in a choice of finishes such as Nickel or Antique Gold. If required, we can print text or graphics on plates by Laser Etch, Pad Printing or Engraving. In short, it’s a mixture and both machine and hand finishing to ensure our customers get a quality product both in terms of design and manufacture.

Hamilton Litestat are one of our recommended suppliers. To keep up to date with their news, click here. And, if you are interested in becoming one of our recommended suppliers, click here.