Editor Hamish Kilburn had a ‘day in the life’ with the team at Northern Lights. While at the brand’s headquarters in Chesterfield, England, he was given a tour of the product development process – from laser cutting through to metalwork – and got hands-on in creating bespoke finishes…

It’s not true what they say. You don’t only notice lighting when it is done badly. The lighting schemes inside projects such as Venice Simplon Orient Express, Chateau Denmark, Mayfair Townhouse, Waldorf Astoria, Heythrop Park Hotel, Belmond British Pullman, and a range of superyachts – all featuring statement lighting pieces from Northern Lights – are proof that lighting is (and should) be part of any guest’s first impression.

Image caption: Statement lighting is designed to be noticed inside Galaxy Yacht, designed by Njord by Bergman. | Image credit: Jack Hardy

Exceptional lighting has come to define and, of course, transform interiors in hotels and beyond. But to really appreciate the art and craft of bespoke lighting, designers should take the time to understand the intricate design and manufacturing processes, which is exactly what I was able to do recently when I travelled up to Chesterfield to spend a day with the team at Northern Lights. “We are creators, visionaries and craftspeople,” said Donna Bruce, Managing Director of the company when she started to show me around the factory floor. “We all have a burning passion to transform the sublime into the iconic.” And with that mantra in mind, my journey around the factory floor – delving into the various manufacturing elements, from design to metalwork, polishing to assembly – began.

As we started walking around the site, I caught a glimpse of an enormous lighting chandelier that at the time was in the wiring stages of its manufacturing journey. Just days before I was with the interior designer who, by nothing other than coincidence, was explaining how impactful the lighting inside the project they were referring to was going to be. The designer’s eyes lit up when they mentioned a statement chandelier, the very piece that was being carefully created under the factory roof. Working with Northern Lights and various other specialists, they had designed a bespoke moment in a special area of the hotel – and here it was, resting on a table in a factory, exposed and ready to be assembled.

Projects like these start months before, with various meetings and consultations with the in-house design team, where everything from the form to the finish can be discussed. For Donna Gridley, Head of Creative at Northern Lights, creative problem solving and having an eye for detail allows her to work closely with the in-house manufacturing teams and the artisans. “One of the biggest pitfalls I see is when lighting is not considered at the very early stages,” she explained. “I love that my role allows me pin-point precision thanks to the design and manufacture all being under one roof. No two days are the same. I feel fortunate to work in an area I’m fiercely passionate about, and grateful to continue to collaborate alongside some of the industry’s elite interior designers. They trust us with making their creative visions a reality and I get great satisfaction in seeing the finished projects come to life.”

Image caption: The lighting scheme playing a major role inside Sopwell House, designed by Sparcstudio. | Image credit: Michael Franke

The bespoke lighting brand has had many milestones since it first launched in 1987 as a small family business designing and hand-making various products from stained glass. Within just a number of years, the company transformed into one of the key hospitality lighting manufacturers, creating bespoke lighting for luxury hotels, restaurants and retail. “We moved into larger premises and invested in new state-of-the-art machinery in the early 2000s,” Bruce added. “This increased capacity and capability was transformational for Northern Lights, springboarding us into opportunities to work with large global hospitality brands and providers such as ACCOR, Hilton, Four Seasons, Waldorf Astoria and HYATT.”

Today, as well as offering the best quality manufacturing – and metalwork that is, put simply, exceptional, Northern Lights is also able shelter a dynamic design team who are regularly researching future trends while working collaboratively with master artisans and configuring complex manufacturing techniques to consistently deliver spectacular lighting designs. This is where an experienced operations director is needed in order to keep a seamless flow between all aspects of any given project. Cue the arrival of Natalie Shakesheff, who is regularly being welcomely challenged to ensure a bespoke design can be transformed into a physical project. By using her experience and know-how as a senior designer, Shakesheff is able to find solutions for factory processes. Facilitating the company’s myriad of complex projects – especially when many of them are completely new designs – is driven largely by a transparent relationship between manufacturer and designer. “In short, if it’s possible, we will do it,” she said.

Image credit: Northern Lights

The company’s reputation as being a leading and world-renowned lighting manufacturer has led to an impressive and loyal client list. While visiting the factory, I was inspired by the number of active projects I could see being worked – all perhaps at different stages. But in a world that ear-ringingly loud with greenwashing, the environmental and social breakthroughs that the company has achieved in recent years – attaining zero waste to landfill in 2017 being among them – it is refreshing to see that ethics have not been sacrificed as a result of the company’s mission to continue to scale up. On the contrary, the environmental and socially driven attitude of Northern Lights has allowed the designs to be more meaningful. “Over decades we have established close collaborative partnerships with our raw material suppliers,” added Bruce. “These suppliers have been carefully selected and measured against strict criteria, including alignment with our own code of ethics, commitment to workplace equality and green credentials.”

What’s more, I’m told that the team embark on regular supplier visits to ensure the criterion is adhered to and that the quality and, of course, values of the company’s partners continue to reflect what the Northern Lights brand stands for. “We also aim to source as many raw materials as possible within a 60-mile radius to reduce our carbon footprint, support local businesses and localise the supply chain wherever possible,” said Bruce.

Image credit: Oatlands Park Hotel / Northern Lights

It’s amazing to see how far the manufacturing industry has come. While technology has allowed the lighting industry to turn new chapters, so too have the people at the top who are authentically, by example, promoting equality and diversity. Although much more needs to be done to balance the scales, since we have just celebrated International Women’s Day, it is reassuring to see Bruce, a competitive yet compassionate leader in her own arena, surrounded by the respect of her peers. “I am proud to say we have built a strong female leadership team right the way throughout the business, spanning operations, creative, finance, HR and marketing,” she said. “Greater diversity in the workforce attracts and retains talent and broadens lateral and creative decision-making. Sadly, women are still under-represented in manufacturing and the number of women in leadership roles remains disproportionately low.

“As a business we’re committed to changing this and challenging the archaic gender stereotypes still present. We actively encourage women to join our manufacturing team where we ensure they get mentorship and support. It’s important that we continue to increase the visibility of our female leaders and staff, whilst offering real opportunities for career progression. Women can have a tough time climbing the career ladder in manufacturing – we’re here to change the script.”

If you have ever wondered the capabilities of a company like Northern Lights, then look no further. From signature to bespoke, the company rarely – if ever – turns down a project. “If it’s possible, we’ll do it,” is the general mindset from the design team. And with all challenging projects come the juicy stories, such as the Breuer chandelier, 2,200 mm high with five modular tiers with a largest diameter of 1,000 mm, that Gridley designed for the stand at HIX in 2022.

Image caption: Breuer Modular chandelier, part of Northern Lights’ signature collection, that was exhibited at HIX 2022. | Image credit: Michael Franke

“It was initially designed as an imposing, dramatic five-tier chandelier, weighing in at a hefty 250 kilograms,” the designer explained. “The original design was used to show the scaled-up capabilities we could offer. However, the true design approach allowed for modularity, scalability and flexibility across multiple spaces, budgets and visions for a truly versatile installation that also doubles up as a sculptural artistic piece.

“For my showcase piece at HIX 22, I felt that a modular brutalist-inspired design would work well with the rest of the collection I was designing and curating at the same time – I decided Verdigris as an acid finish was also long overdue a revival and my instincts were correct. The Verdigris worked perfectly as a foil to the strong linear form of the Breuer and was further softened by faux alabaster diffusers to the LED lights.”

-

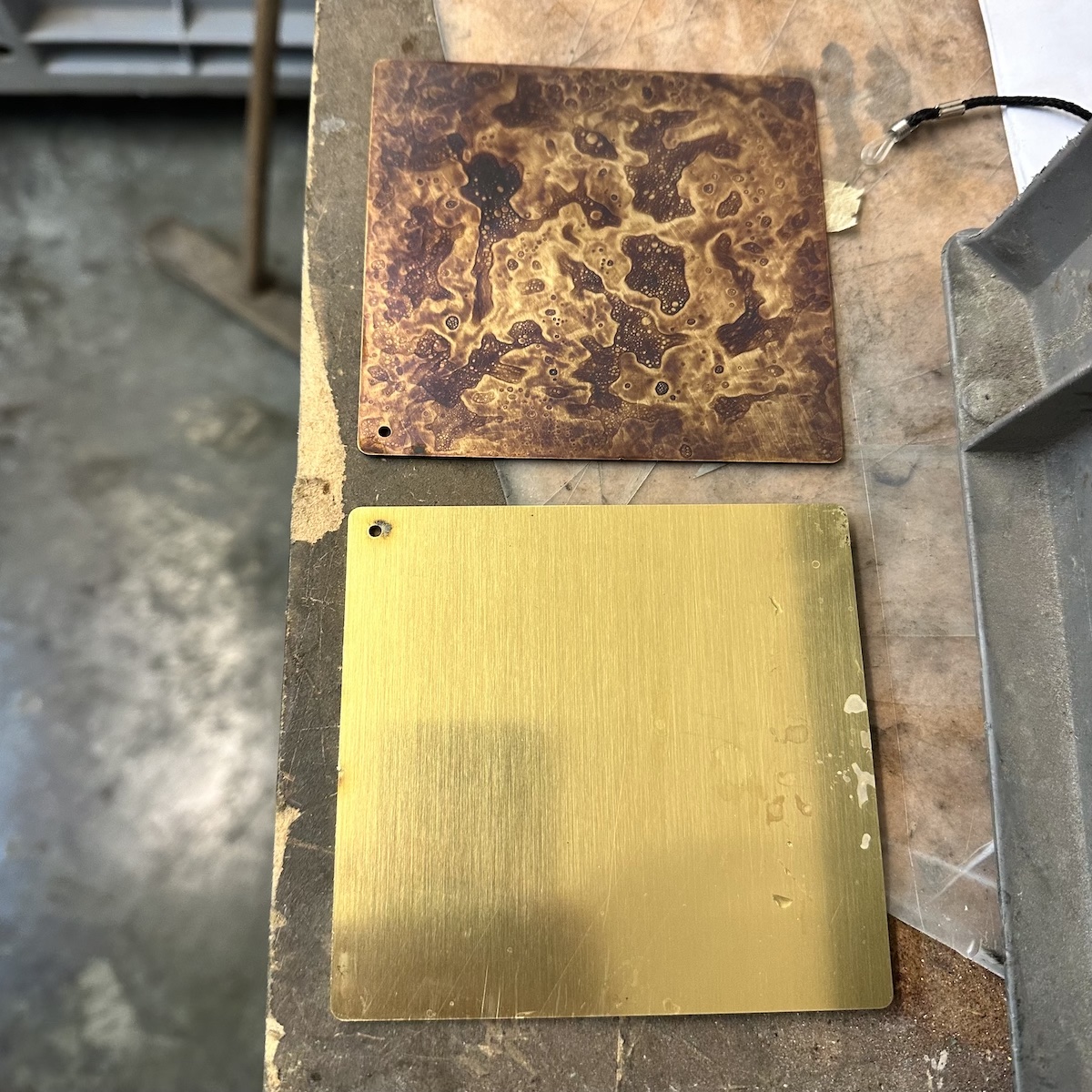

- Image caption: Editor Hamish Kilburn getting hands-on in the finishing department, experimenting with acid finishing. | Image credit: Hotel Designs

The highlight of my time with the Northern Lights crew was getting a hands-on experience; learning how to acid finish with the creative chief herself, Gridley. The enthusiastic and immersive masterclass, experimenting and learning the delicate art and chemistry of the acid finishing process – where there are many elements at play – left me with a new-found respect for the team who are regularly asked to ‘match’ finishes. This aptly left me to draw the conclusion that this, what Northern Lights do, is not lighting, it is art, science and innovative design wrapped into one – long may purposeful, British lighting manufacturing thrive.

Northern Lights is one of our Recommended Suppliers and regularly features in our Supplier News section of the website. If you are interested in becoming one of our Recommended Suppliers, please email Katy Phillips.

Main image credit: Northern Lights