Inside the factory: all under one roof with Northern Lights

With its roots in stained glass design and a penchant for innovation, Northern Lights has always been a versatile manufacturer, and carries out all design and production under one roof. The Hotel Designs team was lucky enough to visit said roof, in Chesterfield, to find out exactly how Northern Lights has grown from small family business to global lighting brand…

Originally formed in 1987, Northern Lights started life as a family business specialising in handmade stained glass design before progressing into the internationally acclaimed lighting manufacturer it is today.

Transforming spaces through its exquisite artisan lighting for over 35 years now, Northern Lights is responsible for illuminating projects such as Venice Simplon Orient Express, Chateau Denmark, Mayfair Townhouse, Waldorf Astoria, Heythrop Park Hotel, and Belmond British Pullman to name just a few.

Hotel Designs was delighted to be invited to the Chesterfield factory earlier this year for a behind-the-scenes nosey for an exclusive peek at the team’s current work.

We met with Donna Bruce, Managing Director and Michael Jackson, Head of Design, for a guided tour of the factory. Donna tells us how prior to moving to this unit, the business was set over several buildings, where the products would have to be moved from one place to another during the construction process.

“We moved here in the early 2000s, and it meant that we could have everything under one roof. It was slightly bigger than we needed at the time, but we’ve also had to extend as we’ve grown. Ultimately having all of the processes under one roof obviously became a huge advantage.”

The factory has an impressive footprint of 38,000 square foot, making them one of the largest purpose-built lighting manufacturing facilities in the UK. By keeping as much of the lighting manufacture as possible under one roof, the in-house team is able to maintain full control of the quality at every stage of the process.

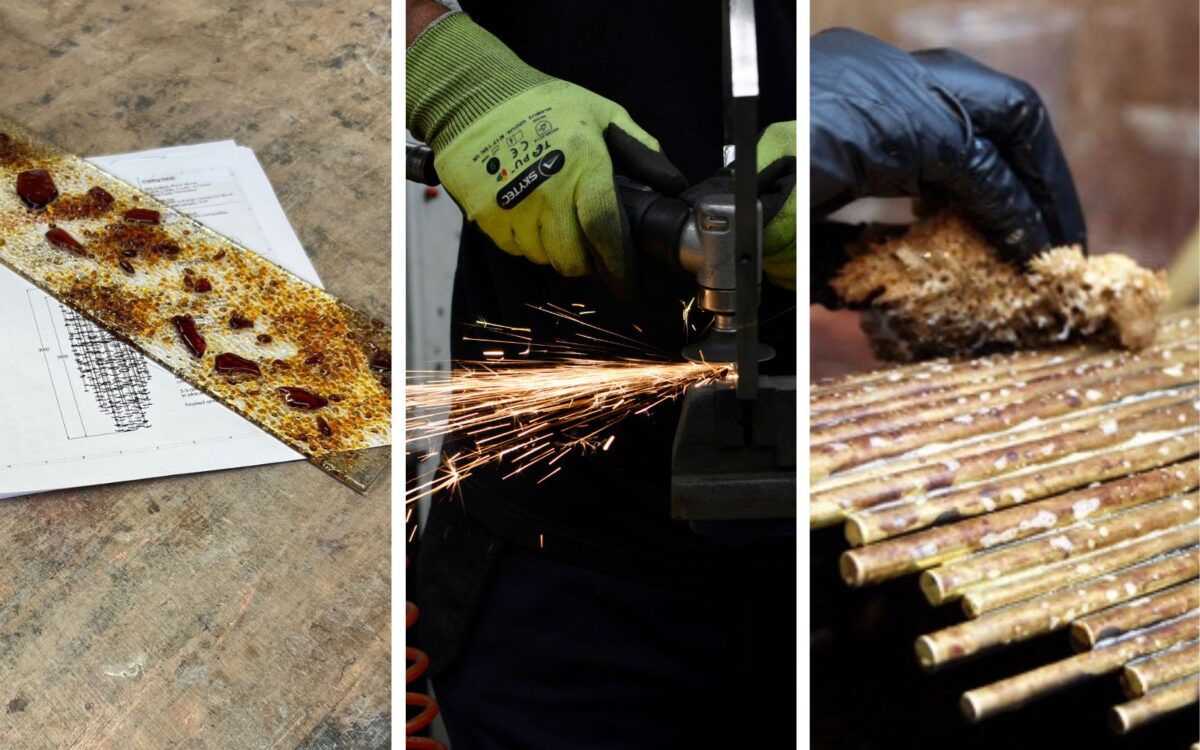

Each area of the factory is dedicated to a different part of the process. Glass manipulation, welding, laser cutting, tooling, metalwork, wiring, finishing and shade departments are perfectly set up to move the product smoothly through each process required.

Telling us about the history of the business, Donna explains that Northern Lights started out by making stained glass. “That’s where it started, church windows, Tiffany shades, that kind of thing, that was the original owner, he used to make them.” Almost on cue, a member of the team, Jamie, walks by and Donna tells us he’s been here since he was 16 years old and used to make stained glass with the original owner. “There are lots of people who’ve been here since the very beginning, which is amazing, isn’t it? I’ve been here 26 years. My father and one of my aunties worked here. Whilst I was still studying, I worked in the factory. After my studies I didn’t know what I wanted to do then I got a call from the original owner’s wife asking if I’d like to come and work for them in sales – that’s where it started for me.”

Donna found she quickly developed a good rapport with clients as she understood the process and engineering involved for each product having already worked in the factory, so as a sales person was able to advise what could or couldn’t be done and work out costings quickly. She soon became rooted in the business, which resulted in senior positions and management.

We take a walk around the factory and stop in the glass department to admire some beautiful almost finished products for a top-secret client… we’re sworn to secrecy, which is a hard pill to swallow as a journalist, but a secret it must be.

I ask about the craftsmanship that goes into making stained glass and the other bespoke elements Northern Lights is so well-known for, and whether it’s difficult to find people with the skills and knowledge required.

“We still get a lot of interest and enquiries for that kind of craftsmanship,” Donna says. “In terms of being able to employ people that can do it, that have those skills, it’s really important to keep hold of people that can. That flows through the rest of the business, too. Certainly within metalwork and fabrication, we have to run our own internal training programs. We have our own milling machine. We pride ourselves on mixing traditional with new technology.”

Donna shows us a lathe milling machine in use that’s 120 years old, and right next to it is a brand-new laser cutting machine to show us their methods are also a mix of traditional and cutting edge.

“A lot of people don’t know the extent of what we can offer, what we can do,” she says, “but you show them these kinds of elements and they’re inspired. It kind of spirals when we bring people around and present what we can offer.”

Working directly with interior designers is a favourite part of the job, and Donna and Michael tell us how they’ve had some interesting briefs once designers understand Northern Lights’ capabilities.

“We’ve seen it all,” Donna laughs. “We did a whole brand years ago where every single light fitting was made from an oil drum, we’ve had ostrich feathers, wall lights made from jockey’s hats, canoes, we had a client ask if we could cover the product in AstroTurf, we said yes, if that’s what you want!”

“We don’t say yes to everything, but luckily Michael has some extremely creative people in his team who don’t see anything as a problem. They love a challenge. Where we really excel is with our metalwork capabilities. We’re metal experts and make our own metal moulds for glass forming.”

Michael explains that he and his team work from all kinds of different design briefs. Often designers will send through detailed sketches and other times clients will ask for the Northern Lights to come up with a design based loosely on a description like ‘create a steampunk-esque pendant with a Mad Max twist’ or ‘a fish with lights inside it’.

“There was one time a designer asked if we could make a jellyfish pendant. And I was like, well, what are you thinking? You know, give me an idea. And he literally sent us a picture of a real jellyfish!” Michael laughed. “We made it though; it was installed in a shopping centre for years.”

“It’s the design team and all the artisans working really closely together to say, how do we make this work? What about this material? Because it will hold the structure without adding too much weight. Or how can we, you know, make this into something that looks as they want, but is going to be safe and is going to be right for the brief. There’ll be common elements that we can bring in from other projects, historically, items that we know work.”

Donna tells us how the design team is always experimenting with different materials and effects. “We’re doing experiments with gold and copper and silver leaf fusing, and the effects are quite different to what you’d expect, but quite unique and interesting.” Currently, 55 custom metalwork finishes have been developed as beautiful finishes that can be combined with any design.

I ask about the general process of concept and design to delivery and Donna surprises me by telling me lead times are usually only a matter of weeks. “It depends on the complexity of the item, but it’s usually a week or two in the design stages, then the drawings go out to be reviewed and approved, so then from approval it might be four, six, or eight weeks, depending on the complexity and scale of the item. Larger bespoke pieces and things that are obviously going to take a lot more thinking about both from design and from the factory floor, we would probably say eight to ten weeks from point of approval.”

As well as all their bespoke offerings, Northern Lights has a made-to-order Signature Collection that adorns their office showrooms, which designers can choose from as fully functional lighting for full-scale hotel rolls outs, which can all be tweaked to be produced in different colours, sizes, and finishes.

“The lead time on those is then halved,” says Donna, “we don’t have excess product sat on the shelf – we make what we need when we need it, so there’s no waste, and you’re still getting a quality, British made product.”

The passion and expertise Northern Lights brings has helped create some of the most iconic luxury bespoke lighting on a global scale, with their decorative fittings located in a wide variety of stunning hotels, restaurants, private residences, marine and commercial settings. More than a dozen of the projects they have supplied lighting to have been shortlisted for or won awards; quite an impressive accolade!

Last year they were named Finalist at the Brit List Awards: Best in British Product Design for their Helios range of cordless rechargeable lamps. Managing Director Donna Bruce also scooped four award categories and was named an Exemplar Figure at the Top Manufacturer 100 Awards and has been invited back this year to sit on the judging panel.

Main image credit: Northern Lights