6 pitfalls to avoid when specifying stone

https://hoteldesigns.net/wp-content/uploads/2023/10/Wellesley-3.jpg 1000 690 Hamish Kilburn Hamish Kilburn https://secure.gravatar.com/avatar/81d2884aeeac3c45e38c47cacc508c2178bab773320ff2d6a83bdcc803d93aec?s=96&d=mm&r=gIn part two of Hotel Designs’ exclusive editorial series with Stone Federation, we share some of the common mishaps designers and architects encounter when specifying stone…

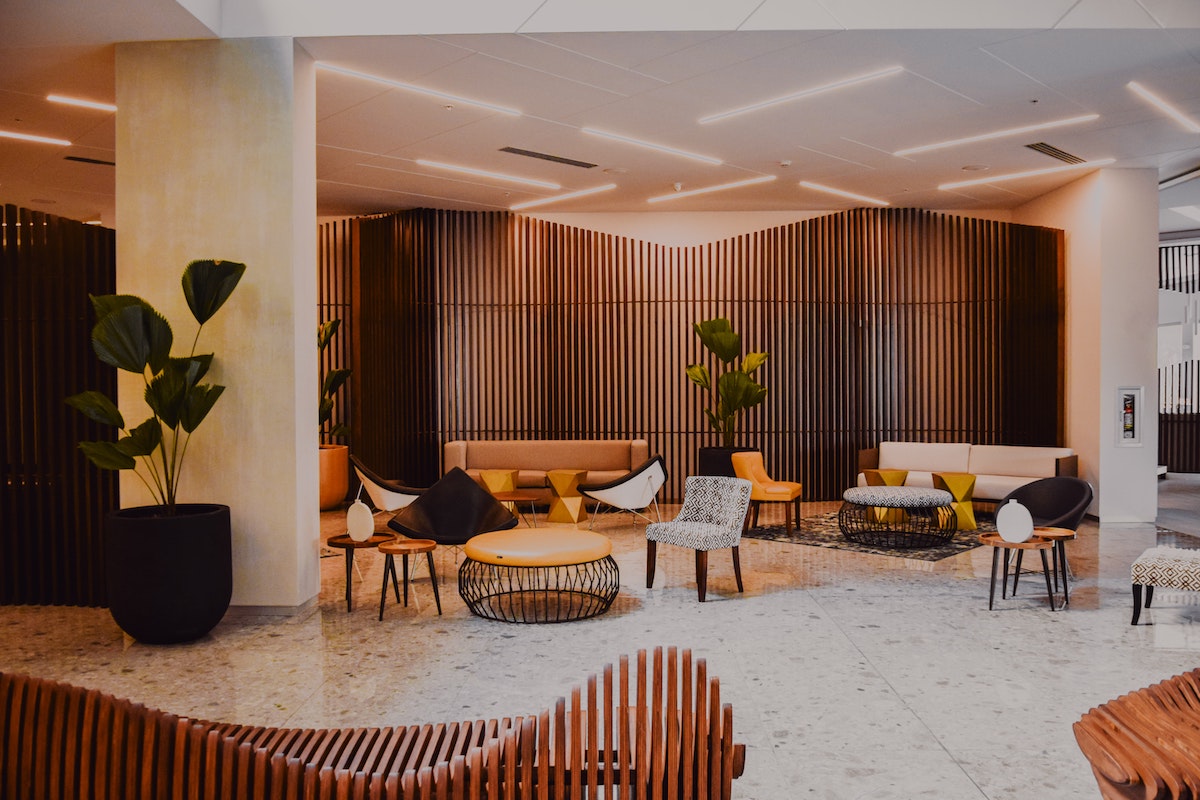

Natural stone is a truly versatile material with a rich history of being used to create memorable, durable and sustainable hotels, both inside and out. It is a material that delivers uniqueness by the bucket load as no two pieces of stone are ever exactly the same, thus enabling hotel designers to create truly one-of-a-kind spaces.

As with any material, the necessary know-how around selection, design and maintenance is key to delivering a successful project. One of the advantages of using natural stone is that it is a material that has been used in hotels for centuries and is supported by a vast wealth of technical research as well as British & European Standards.

The following pointers are designed to be steps on the journey to you delivering a beautiful, durable and sustainable natural stone project.

1) Specifying the wrong type of stone

There is a commonly used adage in the natural stone industry that there is no such thing as a bad stone, just a badly used one, and this holds true project after project. Natural stone is, as the name suggests, a natural material and, just like any other natural product, it will react and respond better in certain situations and less well in others. For example, some stones will work perfectly well as wall linings in lobbies or other dry areas, but would prove to be unsuitable if used in wet areas like shower enclosures.

Engaging with a stone consultant early in the project, pulling on their material expertise, and matching your design vision with the right materials for that application, will help ensure that you specify the correct stone for that specific project.

Image credit: Four Seasons Hotel London at Ten Trinity Square

2) Forgetting it’s a natural product

This might seem obvious, but with the ever-increasing number of man-made, stone-effect products being pushed into the market, it could be easy to forget that natural stone is just that, a naturally occurring material that has not been ground up, mixed with resins and other ingredients and coloured with dyes.

The unique and natural veining, tones and textures found in stone are what make it such a special material. No two blocks of stone will ever be exactly alike, and embracing this as opposed to specifying out any variation or difference in tone and vein pattern is the best way to work with, and not against the natural dynamic of stone. It is vitally important that the stone is viewed under appropriate lighting conditions that imitate the in-service conditions, and that a full range of the stone’s visual characteristics are captured in a range report used as part of the stone supply contract.

Make every specification decision about natural stone through the lens of its natural characteristics, embrace its uniqueness and you will end up with a project that takes full advantage of the organic nature of the material.

3) Trying to move away from movement joints

Like all building materials, natural stone will be impacted by changes in environmental conditions (heat, impact and traffic), which is why it’s important to provide stress-relieving movement joints.

When designing a natural stone floor, there a several questions that will help deliver a durable scheme and avoid failures in the floor.

The first step is to ascertain whether you need a movement joint. Simply put, where the distance between restraining surfaces including perimeter walls exceeds two metres, a perimeter movement joint must be installed. Intermediate movement joints are required where the distance exceeds 10 metres. With underfloor heating, the natural stone flooring should be divided into bays of up to 40 metres squared, with a maximum bay length of eight metres.

It’s also important to consider whether the floor will be subject to light or heavy loading, and whether there’ll be underfloor heating. If the floor will be exposed to low loading, or in a low traffic and impact area, a sealant would provide a suitable movement joint. If the floor is in a higher traffic environment a pre-formed movement joint, typically comprising metal side plates with a flexible synthetic rubber core may be more suitable. If there is an underfloor heating system, the pipes or cables should be located to ensure that the system is contained within the pattern of the movement joints.

Hotel interior designers should also take drying shrinkage into account because stone, like all finishing materials, reflects movements arising from supporting substrates. In the early period of a floor’s life cycle, movement occurs primarily from the drying shrinkage of the slab and screed. As a rule of thumb, a typical 10 metre span slab will experience drying shrinkage of three millimetres irrespective of design, depth or amount of reinforcement used.

Image credit: Stone Federation

4) Forgetting that slip resistance can affect material appearance

When discussing slip resistance within hotel design, it’s important to have a basic understanding of a few of the fundamental points relating to the equipment used to establish slip resistance and the means of assessment of results generated.

Most of the guidance and specified in-service performance criteria will quote values in Slip Resistance Value (SRV) or Pendulum Test Value (PTV) – these are the same.

A material’s slip resistance is determined by several factors. The choice of stone, choice of finish and choice of sealant or impregnator will all have an effect on the slip resistance properties of the finished floor.

When deciding on which material to specify it’s important to understand how the material’s appearance might change when the texture that enables that material to achieve the required slip resistance rating is applied. For example, a polished marble will look very different to a honed marble, as the polish will reflect light whereas a honed finish will absorb it, making the colours of the stone appear more muted. Considering these factors early in the project will help avoid challenges further down the line.

“This comes back to the point about there being no such thing as a bad stone, just a badly used one.”

5) Aftercare treated as an afterthought

Natural stone, like any other material, requires maintenance to keep it looking and performing at its best. Understanding the geology of the material specified, its porosity and absorption is important as different stone types will require differing levels of care and maintenance. It’s also worth noting that heavily trafficked areas will require more maintenance than those that are seldom used.

One of the most common pitfalls made in the maintenance of natural stone is the use of incorrect products that damage the material. The use of acidic products should be avoided as they can remove any surface sealant or in extreme cases damage stone. It is best to use carefully considered ‘proprietary’ stone cleaning products that will typically be of neutral pH or mildly alkaline.

Working with your stone supplier to develop an ongoing maintenance plan before project completion will help manage client expectations from the outset.

Image credit: Adare Manor

6) Unexpected interactions

Considering the environment in which the stone will be used is key to avoiding one of the most common pitfalls in the use of stone in hotels: staining or marking caused by products like wine, make-up or other acidic substances or staining caused by a repeatedly wetted stone without the required drainage. This comes back to the point about there being no such thing as a bad stone, just a badly used one.

Taking into account the substances that the stone will interact with will help you specify the right stone for that environment.

Natural stone is a truly unique material providing hotel designers with a whole host of unique tones and textures and the ability to deliver sustainable, long-lasting projects. By considering the points raised above, you can help avoid some of the most common pitfalls. Stone Federation also always recommends working with a stone consultant as early in the project as possible, and make sure that you choose a Stone Federation company at each stage of the process to ensure that you are working with the best companies and materials.

> Since you’re here, why not read the first article in this series about ‘measuring sustainability in surface design‘, or Stone Federation’s collaboration with Squire & Partners, Stone Tapestry?

Main image credit: The Wellesley Knightsbridge