On the outskirts of London, in Chessington, Editor Hamish Kilburn arrived at Dernier & Hamlyn’s headquarters; the place where bespoke lighting concepts that, on paper may look impossible, become realities…

Dernier & Hamlyn, the lighting geniuses behind projects such as Nobu London Portman Square, NoMad Las Vegas, The Standard London, Four Seasons Hotel Hampshire, Adare Manor and Kimpton Fitzroy London, among others, will celebrate its 135th anniversary next year – it has come a long way from its early days as a lampshade manufacturer. In fact, I was told by Michael Mulhall, Director at Dernier & Hamlyn, that in the 1930s, and throughout the war, the company, like all surviving businesses do, adapted in the most heart-warming of ways. “All of a sudden, due to the social and financial pressures of war, the demand for beautiful lighting had muted,” Mulhall said. “Instead, utilising the skill of its workforce and well and truly evolving with the times, the business supplied the British military with parachutes before remerging from that period of history and evolving into supplying high-end bespoke lighting.”

Image caption: Lighting inside Nobu London Portman Square designed by Dernier & Hamlyn. | Image credit: Jack Hardy

Re-emerging at that time on the design scene and gaining a reputation for quality bespoke lighting solutions was not the only time the company evolved. More recently, in 2020, another transformation happened when Dernier & Hamlyn was purchased by NVC.

Image caption: How many people does it take to install the Dernier & Hamlyn chandelier inside Grosvenor Square? Answer above. | Image credit: Dernier & Hamlyn

With large ambitions, a healthy injection of cash – investment being placed on accreditation and savvy marketing opportunities and purchasing state-of-the-art technology – the lighting company was expected to grow. Mulhall described this acquisition as a way to welcome ‘free-thinking’, something interior designers relish when attempting to challenge conventional approaches to lighting and interior design in general.

Image caption: FromBefore and after: The Chandelier inside Grosvenor Square, manufactured by Dernier & Hamlyn, plays a major role in the quintessentially British interior design scheme. | Image credit: Grosvenor Square

Today, the brand’s focus, among other sectors, is to be a leader in the high-end hotel design market, which, with the rise in travel demand for one-off experiences, is crying out for innovative bespoke design – an element that from experience this brand offers with an abundance of style and precision. It’s hard not to notice the passion in the room, amplified perhaps by loyalty – many members of the team have been with the company for decades, and it’s refreshing to see how they, too, have adapted with the company to always stay ahead.

Image caption: Lighting scheme inside Jumby Bay in Antigua, manufactured by Dernier & Hamlyn. | Image credit: Jumby Bay

Adam Coare, Design Manager at Dernier & Hamlyn, who calculated that he had worked on more than 200 projects in the last few years alone, explained how moving with technology, especially 3D printing, has allowed the brand to produce lighting products that reach new levels of luxury, and complexity. In particular, one project challenged him and his team more than some others. “The Penthouse in The Mandrake,” he recalled. “It was an interesting project for us. We manufactured nearly 1,000 aluminium tubes, which all had to be welded together to create an industrial-like statement chandelier.

Image caption: ‘That’ striking chandelier inside the Mandrake London penthouse was created from nearly 1,000 tubes of aluminium. | Image credit: Dernier & Hamlyn

“In addition, and this is the case with a lot of our work, we only had one chance to get it right. Projects like that call for a cohesive team who all work together and communicate transparently.” The factory itself is perfect for that because each member of the team can always see what other departments are working on, separated only by a wall of glass.

Despite the unquestionable talent among the team, one thing they are not trained at is reading designers’ minds. Often presented with very limited information from the client or designer, the team do their best with the resources they have. However, in order to understand how a designer can get the most out working with a lighting manufacture like Dernier & Hamlyn, I asked Philip Lazell, Head of Product, what, specifically, designers should communicate to the team when briefing them on a new project. “As well as designing a beautiful project, we also offer valuable insight, knowledge and solutions if we are provided with enough context around the design,” he said. “I would say elements such as knowing the budget, sharing as many relevant elements about the timeline as possible, understanding the quantities needed and genuinely being transparent with us throughout will allow our team to work in harmony with the designer and the project. Of course, though, we do understand that many of these factors are out of designers’ hands, so we will always do our best to work with what we have got.”

Image caption: A contemporary yet sensitive lighting design scheme inside Jumby Bay, manufactured by Dernier & Hamlyn. | Image credit: Jumby Bay

After the idea of a product becomes a drawing, its design approved and the team at Dernier & Hamlyn have received sign-off from the client, the idea starts to become physical when the manufacturing process begins, and it’s here where the magic happens. For me, walking into this area of the factory felt like walking back into my old secondary school Design and Technology laboratory, but in the future – think laser cutting devices next to bandsaws and heavy-duty welding machines below a structure that tests each of the products.

During my visit, projects being worked on in the factory included reproduction of heritage chandeliers for a restaurant in Mayfair, beautiful fittings for a luxury residence in California, table lamps for a rather famous London retailer and some enormous external lanterns for a refurbished hotel in Oxfordshire – I was told that no day is ever the same, and I can believe it.

One of the most impressive elements to emerge in recent years – and its innovation is really allowing the in-house team at Dernier & Hamlyn to stretch the boundaries in lighting design – is 3D printing. The technology is now used extensively to produce a wide range of prototypes that help designers and their clients to visualise what the bespoke components or light fittings produced in the factory will actually look like when unwrapped.

But beyond prototyping, it is also successfully being used to produce intricate patterns rather than the more traditional styles. This method is not only more cost effective, but also greatly reduces the lead times in getting the patterns to the foundry for casting. For some applications this process can also be utilised for elements of the actual light fittings themselves. Recent advances in finishing techniques now enable Dernier & Hamlyn to get these parts finished to suit the client’s requirements whether it’s a sprayed or a specialised metal finish.

The service complements the existing wide range of skills available from the design team, from the very traditional sketching of initial ideas and concepts, hand drawing of intricate designs, CAD drawings used to inform manufacture and finishing, through to photo realistic renders. When Hotel Designs first learned of the company using this technology in this way, Mark Pye Head of Production at the company, explained just how beneficial this investment has been for the whole team. “Having this printing facility within our own studio means we can now provide a much more flexible and fast service, which is key to our focus on quality and high levels of customer service and satisfaction,” he said.

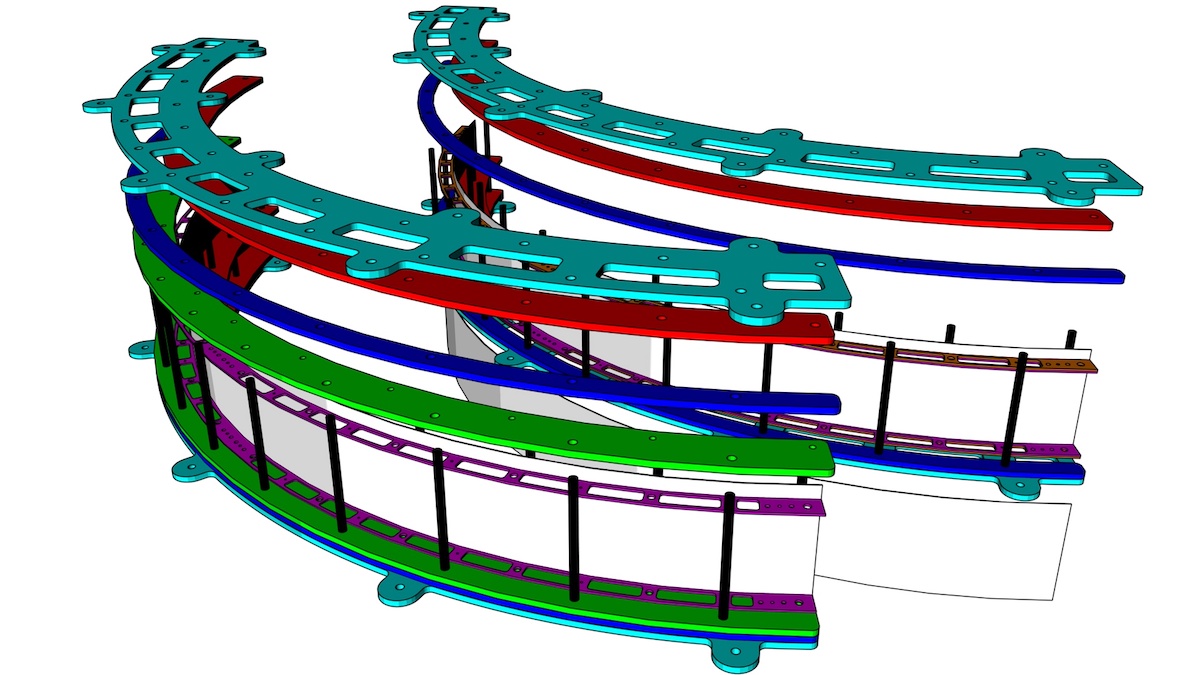

Image caption: A render of the lighting design structure for Holborn Dining, inside Rosewood London. | Image credit: Dernier & Hamlyn

Following my meaningful time with the team driving the company – and lighting manufacturing in general – into the future, I have seen how the company has nurtured its reputation of being one of a select few British companies that designs and manufactures bespoke light fittings in the UK. Most of all, though, it’s clear to me that at Dernier & Hamlyn, quality lighting design comes as standard.

Dernier & Hamlyn is one of our recommended suppliers. To keep up to date with their news, click here. And, if you are interested in becoming one of our recommended suppliers, please email Katy Phillips by clicking here.

Main image credit: Dernier & Hamlyn