We have just broken down exactly what Hamilton Litestat’s Project Support Team offers designers and hoteliers.

Hamilton Litestat, which is Headline Partner for MEET UP North on July 6, has been a pedigree within the hotel sector since the ’80s. In that time, the decorative wiring accessories brand has worked on a range of high profile boutique and international hotel design projects.

This is due, in part, to the behind-the-scenes efforts of its Project Support Team – quite possibly one of the wiring accessory industry’s best-kept secrets – that has been trusted by brands such as Hilton, Accor, IHG, Hotel Indigo, Bespoke Hotels, Whitbread, Marriott, Marine and Lawn Hotels & Resort Group, and Mastcraft Group, among others.

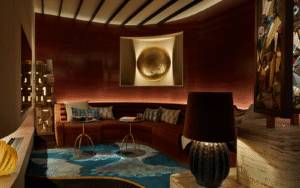

Image credit: IHG/Veerle Evens

The dedicated team of wiring accessory experts are an oracle of creative guidance, design and technical know-how that aspire to be your go-to-team throughout any hotel interiors project – from advice on aesthetics and on-trend finishes to bespoke product designs for projects requiring something a bit special and unique!

With hotels demanding ever more attention to detail in design, and guests expecting access to the latest in lighting control and charging technology, its unique service delivery approach comes into its own.

Hamilton’s structured and immersive approach offers start-to-finish support, which can be broken down into six steps.

Step one: The site visit

Experience has taught the company that it can add the greatest value to a project when involved from an early stage…so why not get them in! A site visit allows the team to fully understand the brief and associated design challenge, in situ, for themselves. From here, the team can make considered product suggestions and help identify and resolve any possible technical issues before they become a problem.

Of course, some clients already know exactly what they want. Hamilton’s team are still keen to share ideas and can offer a wealth of support throughout the project delivery.

Step two: Product selection

With its extensive portfolio of 23 designer collections, in 23 different finishes, most decorative wiring accessory briefs can be met by choosing a collection and finish from its standard designer range.

No one is better placed than the team at Hamilton to understand the merits of each collection and how they can support your award-winning project – with or without customisation.

- Design guidance: With a wealth of industry knowledge, as well as full visibility of existing projects being processed in its factory, Hamilton Litestat can offer you of-the-moment insight into trending designs and finishes.

- Know-how to take cost out of a project: When the budget for wiring accessories is tight but your client’s expectations remain high, the team will work with you to come up with the best value-engineered solution for your project without compromising on the quality or aesthetics, providing an affordable and effective solution that meets the brief.

- Updates on new technology: With aesthetics just one part of the story, Hamilton’s team’s technical expertise means that the company can advise on current electrical regulations, which is especially relevant in large or complex projects.

- In addition, the team can ensure that your decorative wiring solution stands the test of time as technology evolves. A great example of this is the introduction of USB-C charging and the development of combined USB-A&C power sockets which are currently available in a couple of charging options. With knowledge of your requirements, as well as wider industry and cultural trends, the company’s team can help you select the right one for your project.

Step three: Project quotation for your client meeting

With the insight garnered from step one, and decisions made in step two, the team provide a fully costed solution, with product descriptions and corresponding datasheets that include: installation guide, quality standard information, product guarantees and warranties. With this information to hand, you’re able to present and substantiate your design decisions with assurance on quality, technical data and price.

Step four: Free product sample service

Because Hamilton knows that seeing, touching and feeling is believing, its team can not only provide swatches of all of its standard plate finishes, but a production example of the finished product itself. Anything that will complement your mood board and help you sell your design scheme into your client. All samples are produced in its Bristol factory, which means a quick turnaround from them to you.

Image credit: Hamilton Litestat

Step five: Custom-made plates… a special!

Hamilton’s Bristol-based Bespoke Design Team are on hand to turn your product ideas into custom-made solutions when an interior scheme requires something a little different…or even a little special!

Media and control plates can be customised to your bespoke technical requirements and made to match any standard accessories selected as the basis of your decorative wiring accessories scheme.

For example, the bespoke functionality requirements of the accessories at Thornbury Castle Hotel were achieved with bedside plates that included individual toggle-switch control of the room chandelier, table lamps and bedside lamps and a single power socket with 2.1A USB port for charging smart devices. To enhance the guest experience, the function of each switch was clearly etched on each plate. The bespoke plates were based upon the brand’s Hartland collection, which, finished in Antique Brass, with its slim, sleek profile was the ideal box-fix design to harmonise with the ornate brass bedside lamps and dark wood panelling.

To kick-start the process, Hamilton’s in-house engineer will create a CAD line drawing to achieve the initial buy-in of both you and your client. From here, the company’s free sample service and finish swatches can be supplied to support your mood boards, finalise the design and obtain sign-off from your client.

With all design and manufacture taking place at the company’s Bristol HQ, which is set up with projects like yours in mind, the team are able to produce bespoke orders with a swift and seamless turnaround. It is worth bearing in mind that custom-made plates do take a little longer to produce than plates from the company’s standard range, however they will keep you updated on lead times throughout the process to ensure your expectations are met.

Image credit: Hamilton Litestat

Step six: Advice on product lead times

Standard or bespoke – whatever the product mix to make your final list, Hamilton will ensure you’re kept up to date through the whole project, on product lead times and to co-ordinate the delivery of your accessories to site. The team will even pack product in room-by-room boxes if required. Working closely with your electrical contractor – particularly on those more demanding briefs or challenging sites, the team will help to make sure every detail of your brief is met.

Reassuringly expert

Wherever you’re based, the company has a Project Support Team member nearby who will be happy to visit you at your studio or workplace and get your project on the right tracks. Safe in the knowledge that your decorative wiring accessories are in expert hands, you can enjoy the freedom to focus on other aspects of the project, to ensure both you and your client come away smiling.

> Since you’re here, why not read our Q&A with Gavin Williams, Sales and Marketing Director at Hamilton Litestat?

Hamilton Litestat is one of our Recommended Suppliers and regularly features in our Supplier News section of the website. If you are interested in becoming one of our Recommended Suppliers, please email Katy Phillips.

Main image credit: Hamilton Litestat