Inside Balsan: at the heart of French flooring excellence

Nestled deep in the verdant countryside of central France lies a quietly remarkable factory – the home of Balsan, a heritage name in textile flooring. Earlier this year, the Hotel Designs team were invited to take a tour of the production site – a place that revels in the legacy of almost three centuries of craft, innovation, and green ambition…

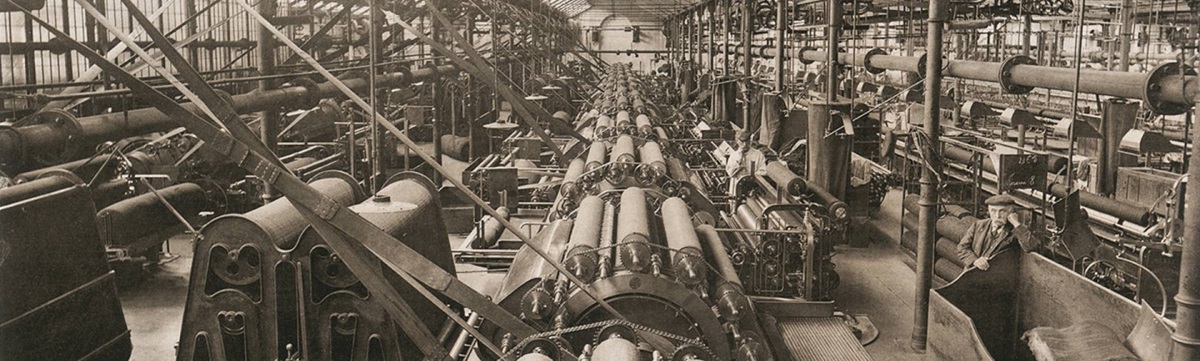

A long-time collaborator of Hotel Designs, Balsan will stick in your memory most recently for their incredible Brit List Awards red carpet entrance as well as the hilarity that ensued at their Clerkenwell showroom during the talks programme at Clerkenwell Design Week this year. But Balsan has a storied history beginning in 1751, when Louis XV granted Jean Vaillé the right to establish a Manufacture Royale at the Château du Parc in Châteauroux. Over time, the Balsan family took the reins, and under Pierre, Auguste, and Charles Balsan, the manufacture grew into a pioneering industrial campus – complete with workers’ housing, a school, a dispensary, and water towers. That same spirit of creativity and responsibility endures today.

Image credit: Balsan

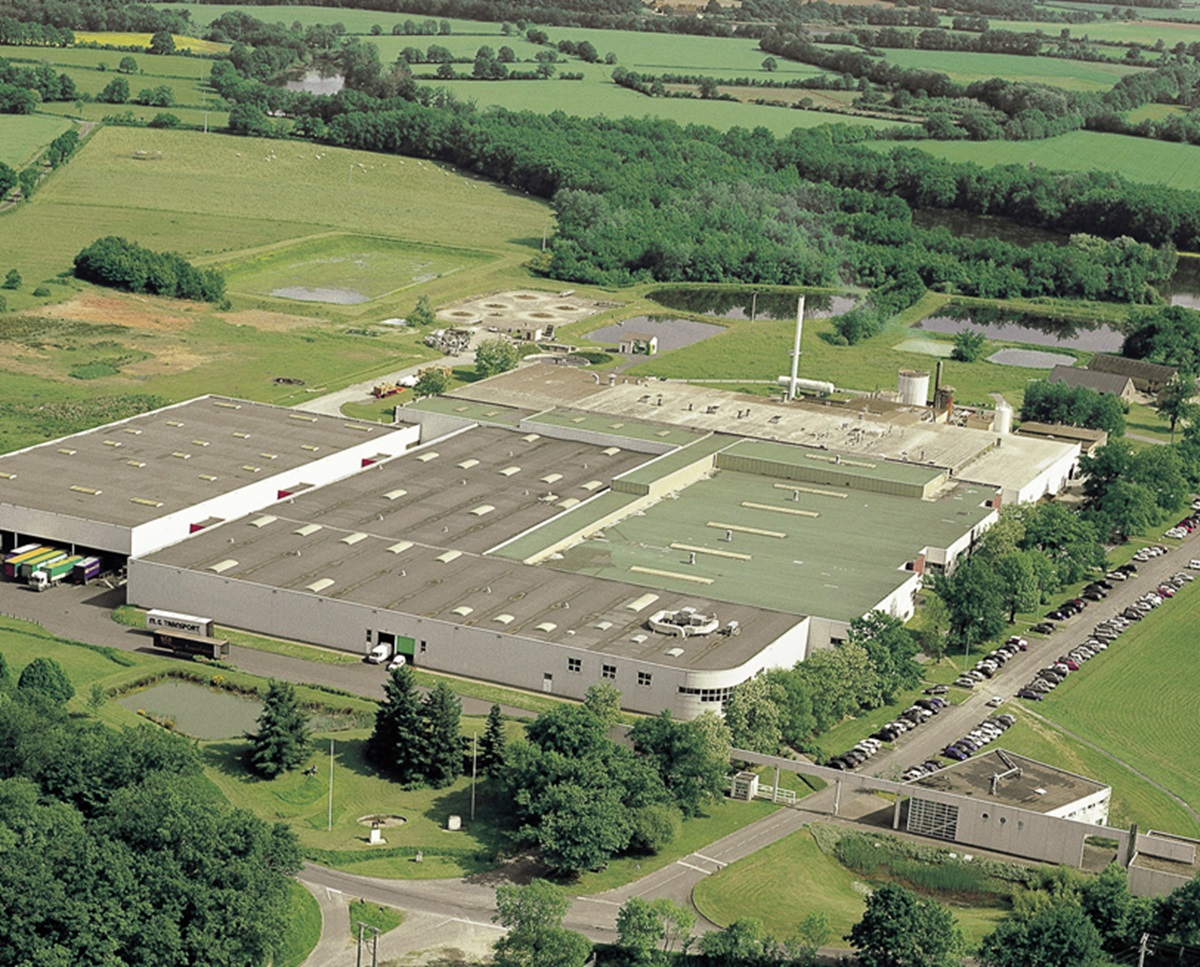

Balsan’s head office and broadloom carpet facility stand on a 45,000m² site in Arthon, while a second factory dedicated to carpet tiles is located in Neuvy-Saint-Sépulchre, just 15km away. On arrival, what’s striking is how gently the buildings sit within their environment. The Arthon site is tucked into the rolling green landscape of the Indre region – a reminder that industry and nature can indeed coexist. Staff point out that Balsan has long championed environmental responsibility, and that commitment has deep roots: the site has been officially classified for environmental protection since 1976.

Image credit: Balsan

Stepping inside, the hum of tufting machines greets you – row upon row of high-precision looms, where yarns in every hue are looped, cut, and shaped into broadloom carpet. Tufting, as Balsan’s leaders discovered in post-war America, is central to their process. It enables them to produce dense, luxurious carpet efficiently – but it’s what they layer into that process that makes them unique.

All carpet fibres leave the production line already treated with Balsan Protect, an invisible yet durable coating that repels dirt, stains, and everyday wear. This built-in protection means ease of maintenance for hotels and commercial spaces – no compromise on appearance, no hidden sacrifice to performance. Beyond that, sustainability is everywhere. Balsan has not only embedded eco-design into its product development but has also committed to circularity: they recycle yarn waste after production, work with Aquafil to regenerate polyamide into their signature Econyl yarn, and shuttle end-of-life carpet back into a circular recovery chain.

During the tour, we were told about Balsan’s circular carpet prototype, born from the European EFFECTIVE programme, made from 100% bio-sourced nylon derived from sugar beet – a tangible signal of Balsan’s environmental ambition.

Balsan’s environmental credentials are not token gestures. The factory is ISO 14001 certified, which demonstrates continuous environmental improvement. They operate their own water treatment plant and have slashed energy and water consumption dramatically in recent years – 45% energy reduction at Neuvy, for instance.

Perhaps most notably, since 2013, zero waste goes to landfill: Balsan recycles all industrial waste. Their packaging is made from recycled materials, and after use, their carpets can re-enter a recovery loop rather than languishing in waste sites. They’re also part of CRUK (Carpet Recycling UK) and the French UFTM, helping to establish shared systems for end-of-life carpet collection and recycling.

Why this matters for hotels:

From a hospitality perspective, Balsan’s craftsmanship and sustainability make it especially appealing.

- Acoustic comfort: Textile flooring helps reduce impact noise – a critical factor in guest satisfaction.

- Durability and maintenance: Thanks to Balsan Protect and their dense tufting, carpets are resilient and easy to manage.

- Green credentials: Hotels increasingly demand sustainable credentials – and Balsan’s circular, eco-designed carpets tick a major box.

Moreover, the ability to co-create bespoke tiles or rugs ensures that a hotel’s flooring can align precisely with its brand, aesthetic, or guest experience ambitions.

A factory tour is only as revealing as the people you meet, and at Balsan you encounter a tight-knit community of designers, technologists, tufting specialists, colour designers, and quality controllers all moving in harmony. There’s a genuine passion, a shared sense of heritage – and a palpable pride in being part of a brand that is both very French and confidently global.

They talk about how Balsan’s ‘family spirit’ drives their innovation: ideas originate from the design studio, but feedback is real-time, the loop between concept and execution is both tight and agile. The company’s lean structure allows it to respond quickly to the needs of hotel clients, whether that means producing a custom carpet for a boutique chain, or scaling a modular tile range for a large resort.

Simply being in the Balsan factory gives you a sense of having walked through a living heritage site, witnessing the moment design meets industrial precision, and feeling the weight of Balsan’s environmental mission. It’s clear that Balsan does more than make carpets: they craft floors that tell stories, respect the planet, and serve the modern needs of hotels around the world.

At a time when sustainability, customisation, and performance are no longer optional in hospitality design, Balsan stands out as a partner that brings all three. Their factory is not just a place of production; it’s a testament to how centuries-old craft can evolve to shape the future of hotel flooring – beautifully, responsibly, and without compromise.

Balsan is one of our Recommended Suppliers and regularly features in our Supplier News section of the website. If you are interested in becoming one of our Recommended Suppliers, please email Katy Phillips.

Main image credit: Balsan